Posted on

22 January 2015 |

Updated on

19 February 2021 |

Added in

How To

This guide will provide you with the knowledge required to assemble our TexFrame 3D Cubes - in this instance we'll be using a 700mm x 700mm x 700mm cube to demonstrate this.

When you purchase a TexFrame system from us all that you need will be supplied! For each cube display there will be:

- 12 x 3D extrusion lengths (cut to the size you require)

- 8 x 3D extrusion corners

- 1 x alen key

|

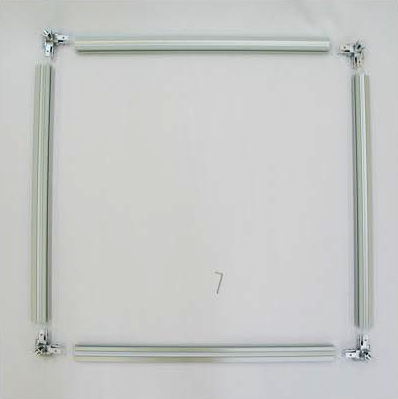

Step 1:

To begin; lay out one side of the cube as we have done.

|

|

|

It's worth noting that the corners and the straight lengths can only be assembled one way.

|

|

|

Step 2:

Slide the corners into a section of the extrusion, use the supplied alen key to tighten the grubs.

(Each join has 2 grubs that need to be tightened.)

|

|

|

Step 3:

Repeat the above step for the opposite end of the same piece of extrusion, so that you have formed a U shape.

|

|

|

Step 4:

Attach the two remaining corners to the last piece of extrusion.

Step 5:

Once they are attached slide both corners into the U shape & tighten the grubs to complete the side.

|

|

|

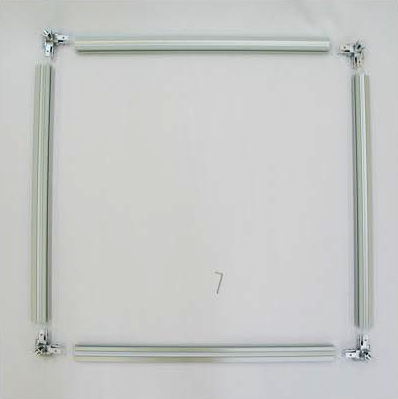

Step 6:

Repeat the above process to complete the second side of the cube.

|

|

|

Step 7:

Attach the remaining 4 pieces of extrusion to the corners, tightening all grubs as you go.

|

|

|

Step 8:

Take the second, completed, side and attach its corners to the vertical pieces of extrusion.

Again, tightening all grubs.

You've made a cube!

|

|

Posted by

William Qian

Posted by

William Qian

William Qian is a Specialist in Exhibition Graphics & Displays, and founder of ADI Displays with a vision in taking creativity through to visual reality.

From humble beginnings, he adopted the latest digital printing technology of its time, producing large format digital printing used for exhibition graphics and portable display systems.

With his love of the creative visual industry, he has established BANNERAD™ Range of Products to accommodate the growing needs of portable display solutions which have been successfully distributed in the sign and display industries.

“It is our focus and innovation that allows our continued success in meeting our customers’ display needs concerning application, preference and budget.”

Related Articles

Posted on 27 Jan 2015 |

Added in

How To |

This guide will provide you with the knowledge required to affix your fabric graphic to an assembled TexFrame.

While there are differences between the profiles of our extrusions the method used to insert the printed fabric graphic is extremely similar for all of them, so we've grouped them to make things easier (the frame used in this case was a 3D TexFrame).

Inserting a fabric graphic into extrusion is fairly straightforward, however like most things, it does get easier with experience. If at any time you find that you're not happy with your progress/finished pr..

We are excited to announce the upcoming launch of our brand-new product: the Looboo Modular Display System. Designed with versatility and ease of use in mind, this innovative display system is perfect for creating eye-catching, professional exhibition booths that can be customized to suit any space or style. Whether you're attending a trade show, conference, or corporate event, the Looboo Modular Display will help you stand out from the crowd.

In the spotlight this month are our custom-built TexFrame fabric lightboxes, a testament to the innovative spirit and technical expertise that define ADI Displays.

Posted by

Posted by